Fall is here, and with it comes the perfect time to ensure your tractors and equipment are in top-notch condition before the colder months set in. Whether you’re a farmer, landscaper, or dedicated equipment owner, performing fall maintenance isn’t just a good idea; it’s essential to extending the life of your machinery and safeguarding its performance.

Neglecting these tasks now could lead to costly repairs, unexpected downtime, or even damage caused by freezing temperatures. But don’t worry—we’ve got you covered. This guide will walk you through the critical steps to prepare your tractors and equipment for the months ahead.

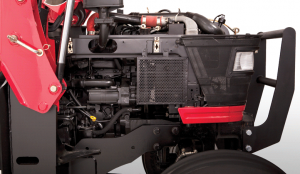

Checking and Changing Fluids

Think of the fluids in your machinery like the lifeblood of your equipment. Keeping them in check ensures your tractor operates smoothly, regardless of the changing seasons’ demands.

1. Oil Maintenance

Start by checking the oil levels and quality before temperatures drop. Old, dirty oil can thicken during cold weather, making it harder for your equipment to function efficiently. Here’s what to do:

- Check the oil level using the dipstick and top up if necessary.

- Change the oil if it’s dirty or dark, as clean oil ensures the engine operates smoothly during those freezing mornings.

Pro Tip: Use oil rated for your region’s temperature range; some oils are formulated for better performance in colder climates.

2. Coolant System Check

The coolant system prevents your engine from freezing or overheating, making it a crucial component to check as we head into winter.

- Inspect the coolant levels using the reservoir or radiator cap (only when the engine is cool).

- Test the coolant with a refractometer to ensure it’s providing adequate freeze protection.

If needed, drain and refill the coolant or consider flushing the system for optimal performance during extreme temperatures.

3. Hydraulic Fluids

Many tractor operations rely on hydraulics, ensuring implements like loaders or backhoes work seamlessly. Cold weather can thicken hydraulic fluids, reducing efficiency and putting stress on your equipment.

- Check fluid levels and ensure there’s no contamination.

- Use a manufacturer-recommended, cold-weather-compatible hydraulic fluid if necessary.

Keeping your fluids in check is a small investment that can prevent much larger problems down the line.

Caring for Your Tires

Your tires are the foundation of your equipment, and neglecting them can affect performance and safety. Here’s how to keep them ready for any job fall that comes your way.

1. Monitor Tire Pressure

Fluctuating fall temperatures can cause tire pressure to drop. Uneven or low pressure can lead to wear and even costly blowouts. Use a tire gauge to check that your tires are inflated to the manufacturer’s recommended levels.

2. Inspect Tread and Damage

Check for cracks, punctures, or uneven wear that could compromise safety or traction. If your tires’ tread depths are too low, consider investing in replacements before wet, icy conditions take a toll.

3. Proper Storage

If you plan to store any equipment for the winter, elevate the tires to reduce prolonged pressure on a single point. Store the equipment in a covered area to protect tires from direct exposure to cold, which can lead to cracking.

Inspecting and Servicing Batteries

Cold temperatures can put a major strain on your equipment’s battery, and a dead battery will grind operations to a halt. Take these steps to ensure your battery survives the fall and winter months.

1. Check Battery Health

- Inspect the battery terminals for corrosion. Clean them with a baking soda solution and a brush, if needed.

- Use a multimeter to test the voltage. A healthy battery should read a charge of 12.6 volts or higher.

2. Service and Replace if Necessary

If you notice your battery struggling to hold a charge, it might be time for a replacement. Investing in a high-quality, weather-resistant battery ensures your equipment is job-ready.

Pro Tip: Store spare batteries in a cool, dry place to avoid damage during freezing conditions.

Cleaning and Storage

Proper cleaning and storage are non-negotiables when it comes to extending your equipment’s lifespan. Think of this step as safeguarding your investment for the future.

1. Deep Clean Your Equipment

Mud, debris, and moisture can wreak havoc on your machinery if left unattended.

- Use a pressure washer to remove dirt from all surfaces, paying close attention to hidden crevices.

- Dry the equipment completely to avoid moisture buildup and rust.

2. Store in the Right Environment

Keep your equipment in a dry, covered area, such as a barn, garage, or shed. Protecting it from moisture and extreme temperatures can prevent long-term damage.

3. Use Protective Measures

Add a weather-resistant cover for added protection, and lubricate moving parts to reduce friction and prevent rust. It’s a quick effort that pays off when spring rolls around.

Keep Your Equipment Running Strong

Preparing your tractors and equipment with proper fall maintenance is key to preventing downtime, costly repairs, and headaches once winter arrives. Checking fluids, servicing batteries, maintaining tires, and storing equipment properly ensure your machinery stays in peak condition and is ready to tackle any task, no matter the season.

Need expert assistance to get the job done right? Our team specializes in keeping tractors and equipment in optimal condition year-round. Contact us today for service you can trust!